The company follows documented procedures and well established SOP to ensure better quality control right from procuring raw material to finished product. Our products are BSI Approved and QMS is ISO 9001:2015 Certified.

With fully Integrated Plants,In house testing labs, 300+ Professionals Workforce( Skilled, Semi Skilled and contract labours) and 30 years of extensive Experience, we can fullfill any requirement within timeframe.

Customer requests are fully taken into consideration and information is passed on at every stage of the manufacturing process.

Established in 1990 as amongst India's northern region's first integrated private sector steel companies,Rajdhani Group offers premium quality HR Coils and ERW Pipes that are extensively used as a raw material in various sectors like infrastructure, electrical, automobiles, agriculture, sewerage which is directly Manufactured from in-house Integrated steel plant. With in house the state-of-the-art testing facilities and with the help of spectrometers and a fully well equipped lab, Rajdhani Group stands amongst the Emerging ERW Pipe Suppliers and Exporters in India.

We belive in Recycle, Reduce and Reuse to control Iron Ore consumption for steel making. Our Steel making plant uses more than 90% Steel Scraps for Steel production. We import steel scraps from varrious Asian and Europian countries. After procurement scraps are segrigated and further precessed to remove impurities before sending it to induction Furnace

Under this the processed scrap is Melted at 1640°C through Induction furnace.The team of metallurgist and other professionals follows documented procedures and well established SOP keeping in mind the quality standards and and varorious international standards.

Our plant is installed with fully automatic Continuous Casting Technology for fast paced production of MS billet without compromising quality. This save time, cost and energy yet emproving yield and quality of steel at same time. In the casting process, molten steel from the ladle flows through the tundish into a mould. Within the mould, the molten steel freezes against the water-cooled copper mould walls forming billets.

Under this integrated steel plant the MS billets are hot rerolled at a temperature 1000°C through fully automatic rolling mill to form HR Coils.

This process is fully monitored by a team of professionals which follow prescribed SOP to make sure that optimum quality is achieved and is according to standards

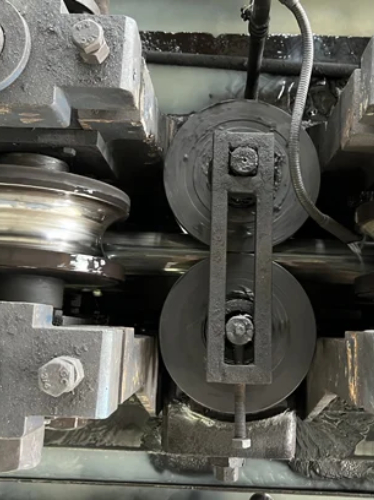

ERW Pipes are manufactured by cold forming of steel coil into various shapes and into various varieties all according to the various national and international standards

The raw material of ERW Pipes i.e. Steel Coils is fully procured in-house as part of the integrated steel plant. Rajdhani brand has been constantly executing need based demanding orders for ERW Pipes to meet the requirement of sectors like Agriculture, Oil and Gas, Public Health, Housing, Irrigation, Engineering etc.

At Rajdhani, the concept of Total Quality control is an integral part of the manufacturing process.To ensure better performance,men and machines are properly harnessed from the raw material stage, production stage and till the goods are dispatched.We are well equipped with a modern metallurgical laboratory .Stage inspection is carried out to ensure proper surface finish, weld, correct diameter,wall thickness,length and weight.Based on random sampling,the final product is subject to critical testing to ensure that the weld, tensile and compressive strength meet the required standards.

After getting approval from the quality team the finished ERW pipe is fully stamped and graded according to the composition and are dispatched according to sale orders.

"I get in my truck, put on the speaker phone and audio text my order to Rajdhani Castings. From there, he takes care of everything and all I need to do is show up to pick-up the material."

"I needed HR Strip in huge amount within a month, I called them and product was delivered to me even before deadline without compromision on quality of product. "

"I just gave them the composition i needed for my engineering project and they delivered it very soon in same chemical composition"